除臭循环泵常用材质介绍<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

一、厌氧提升泵概述<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

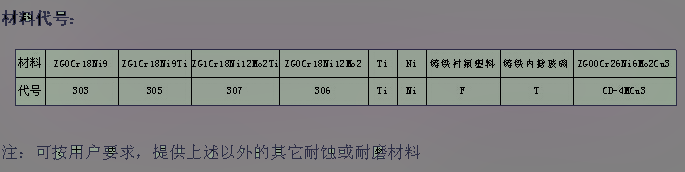

厌氧提升泵根据用户输送介质的不同,泵的过流部分有氟塑料、搪玻璃、各种奥氏体不锈钢、金属钛、金属镍等,因此广泛应用 于输送低温、常温或高温腐蚀性介质,并允许含有一定量的固体颗粒,主要应用于化工、石油化工、炼油、冶金、轻工、医药等工业部门。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

二、厌氧提升泵性能范围<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

流量:<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>2-480m³<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>/h 扬程:<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>3-150m 工作压力≤<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>2.5Mpa 工作温度:<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>-80℃<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>-300℃<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

三、厌氧提升泵采用标准<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

额定性能点和安装尺寸符合<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>ISO2858、<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>ISO3661,技术条件符合<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>GB/T5656-94(等效于<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>ISO5199)<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

四、厌氧提升泵设计特点<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

提高了厌氧提升泵运行中故障率高的机械密封和轴承的寿命。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

①用加粗轴,增大轴刚度<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

②轴承加大,采用双列向心推力球轴承<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>,滚子轴向游隙小<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>,轴承寿命><SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>2.5万小时<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>,延长机械密封寿命。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

③叶轮和泵轴用螺纹连接,密封可靠,拆装方便,抗汽蚀性优于<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>IH泵。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

④轴承箱空腔宽敞,机械密封工作条件好,寿命长。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

⑤可供水冷式或风冷式轴承箱,或水冷式轴封箱,中心支撑泵体。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

⑥可按美国<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>API610标准第采用集装式机械密封。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

⑦可供多种轴封形式:单端面、双端面、串联、内装、外装式机械密封;副叶轮、填料密封,可按美国<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>AP1610标准供应机封辅助系统。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

⑧可配压力传感器或电机保护开关来防止过载损坏电机和断液损坏机封。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

⑨可配套电机调速装置,随时调节流量,并可和液位计联动自控。也可和流量仪联锁自控所需流量。<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>

<SPAN lang=EN-US style="FONT-FAMILY: " Calibri?,?sans-serif??>